How a BESS System is Built: From Concept to Commissioning

Battery Energy Storage Systems (BESS) are reshaping how we think about electricity. They’re making renewable energy reliable, stabilizing grids, and even replacing traditional fossil-fuel plants in some applications.

It’s not as simple as stacking some batteries in a box. Building a BESS is a highly technical, multidisciplinary process that spans electrical engineering, software, construction, logistics, safety, and regulation.

This post walks through the entire BESS development process—step-by-step—from design to deployment. Whether you’re a developer, engineer, investor, or just curious, here’s how it all comes together.

“But how exactly is a BESS system built?”

- Project Scoping and Feasibility

- Define the Use Case

Before anything gets designed, the first step is to define the purpose. A BESS can be used for many things:

- Backup power

- Time-shifting renewable energy

- Peak shaving

- Frequency regulation

- Grid resilience

Each use case affects design decisions—from sizing to chemistry to software.

- Load and Energy Analysis

Next, engineers analyze energy consumption and generation patterns. This involves:

- Reviewing utility bills or meter data

- Modeling daily/seasonal demand

- Forecasting energy generation (if renewables are involved)

This determines how much capacity and power the BESS needs.

- Site Assessment

The project team assesses the physical site:

- Space availability

- Grid connection options

- Environmental conditions (temperature, humidity, flooding risk)

- Permitting requirements

- Proximity to sensitive infrastructure

No two sites are the same. Each presents its own constraints.

- Financial Modeling

Developers create financial models to see if the system makes sense. This includes:

- CapEx (capital expenditures)

- OpEx (operating expenses)

- Payback period

- Revenue streams (incentives, energy arbitrage, demand response)

If the project passes these hurdles, it moves to design.

2. System Design

- Choose Battery Chemistry

This depends on performance, cost, lifespan, and safety needs. The most common choices are:

- LFP (Lithium Iron Phosphate) – Long cycle life, thermally stable

- NMC (Nickel Manganese Cobalt) – Higher energy density, used in EVs

- Flow batteries – Long-duration storage, scalable, non-flammable

Each chemistry affects everything downstream: cooling needs, control systems, footprint, and cost.

- Determine Power and Energy Ratings

Two critical specs define every BESS:

- Power (kW or MW) – The rate at which the system can charge/discharge

- Energy (kWh or MWh) – The total stored capacity

These are often referred to in tandem: for example, a 10 MW / 40 MWh system.

A longer-duration BESS (higher energy-to-power ratio) is good for shifting solar power to nighttime. A shorter-duration system is better for fast frequency response.

- Electrical Design

The system needs to be electrically integrated with the site or the grid. This includes:

- Inverter sizing and selection

- Switchgear design

- Transformer specification

- Protection systems (breakers, fuses, relays)

- Grounding and earthing

- Fire and arc-flash mitigation

Every detail must comply with local electrical codes and safety standards (like NEC, IEEE, or IEC).

- Thermal Management Design

Batteries hate heat. Engineers must ensure the BESS stays within a safe operating range.

Options include:

- Passive ventilation

- Air conditioning

- Liquid cooling (for dense systems)

The bigger the system, the more critical and complex cooling becomes.

- Enclosure and Form Factor

BESS systems come in different form factors:

- Cabinets – Often used for commercial or small industrial systems

- Shipping containers – Standard 20/40-ft containers for utility scale

- Custom buildings or skids – For large, integrated sites

Enclosures must handle weather, theft, fire, and more.

- Procurement and Manufacturing

- Battery Cell Sourcing

This is a global supply chain game. Battery cells are usually sourced from major manufacturers (like CATL, BYD, Samsung SDI, or LG Energy). Developers lock in contracts months—or years—in advance.

- Battery Pack Assembly

Cells are assembled into modules and racks. A typical pack includes:

- Cells

- Thermal sensors

- Wiring

- Mechanical support

- Battery Management System (BMS)

This is usually done at specialized facilities. Some developers outsource it; others do it in-house.

- Inverter and PCS Procurement

The power conversion system (PCS) manages the DC-to-AC conversion. Key factors:

- Efficiency

- Response time

- Grid code compliance

- Software integration

PCS suppliers include Sungrow, SMA, Huawei, Tesla, and others.

- Controls and SCADA

The brains of the BESS come next:

- Energy Management System (EMS)

- Battery Management System (BMS)

- Supervisory Control and Data Acquisition (SCADA)

These systems monitor, dispatch, and protect the BESS in real-time. Custom software or OEM systems can be used.

- Site Preparation and Construction

- Permitting and Approvals

Before breaking ground, the developer must obtain:

- Electrical permits

- Zoning and land use approval

- Environmental permits

- Fire safety approval

- Utility interconnection agreements

This step varies widely by jurisdiction and can take months.

- Civil Works

On-site construction begins with:

- Site clearing and grading

- Foundations or concrete pads

- Trenches and conduit runs

- Fencing and security systems

Some projects use precast foundations to speed things up.

- Electrical Installation

This includes:

- DC cabling from battery racks to the PCS

- AC cabling to transformers and the grid

- Switchgear and metering

- Grounding grid

Everything is tested and inspected during installation.

- Fire Suppression and Safety Systems

Most BESS projects now include:

- Fire detection (smoke, thermal, gas sensors)

- Suppression (inert gas, water mist, or aerosol systems)

- Emergency shutoff systems

- Safety signage and protocols

Fire safety is taken very seriously—especially for indoor or urban sites.

- Commissioning

Once built, the system must go through a rigorous commissioning process.

- Mechanical and Electrical Testing

Every component is tested for correct operation:

- Insulation resistance

- Voltage verification

- Ground fault detection

- Cable integrity

- Functional Testing

The system is powered on in stages:

- Power on control systems

- Power on inverter/PCS

- Power on battery racks

- Connect to grid or site

Each stage involves careful monitoring and logging.

- Software Configuration

Control systems are calibrated and tuned for the specific site:

- Charge/discharge limits

- SOC (state of charge) thresholds

- Communication protocols

- Grid services settings

Software updates and cybersecurity hardening are completed.

- Performance Testing

The BESS is tested under real-world conditions:

- Full discharge/charge cycles

- Grid response (e.g., frequency control)

- Emergency shutoff simulation

Performance is verified against the design spec.

- Utility Interconnection

The final hurdle is approval from the utility or grid operator. They ensure the BESS:

- Responds properly to grid commands

- Doesn’t destabilize the local network

- Complies with interconnection rules

Once passed, the system can operate commercially.

- Operation and Maintenance

A BESS isn’t set-it-and-forget-it. It needs active monitoring and upkeep.

- Remote Monitoring

Operators use dashboards to track:

- State of charge (SOC)

- Temperature

- Voltage/currents

- Events or alarms

- Communication health

Systems run 24/7 with alerts for abnormal conditions.

- Routine Maintenance

Every few months or annually, technicians inspect:

- Cooling and HVAC systems

- Electrical connections

- Fire suppression readiness

- Software patches and firmware

Batteries are checked for swelling, leaks, or corrosion.

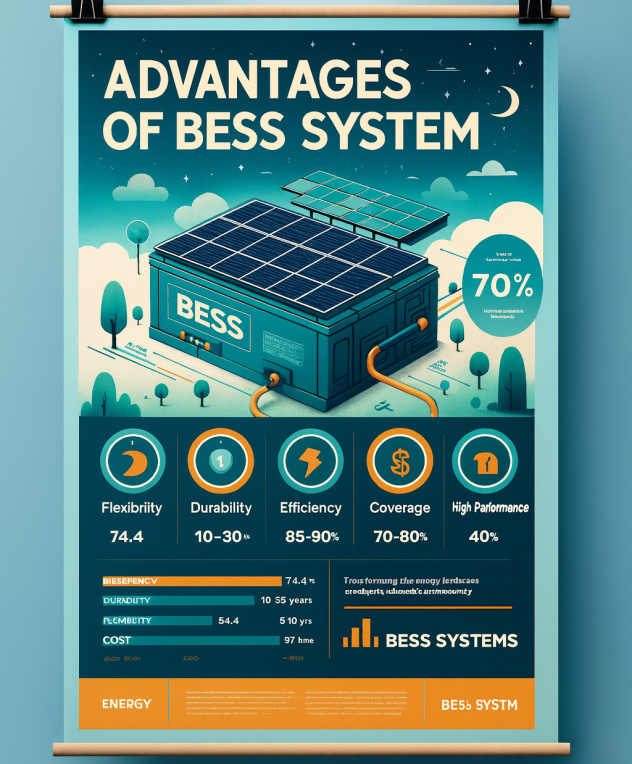

- Warranty and Degradation Management

Battery performance declines over time. BESS systems come with warranties (often 10–15 years). Performance guarantees are tracked through regular testing.

Some systems include automated degradation compensation—extending useful life by adjusting usage patterns.

- End of Life and Recycling

Eventually, every BESS reaches retirement. Then what?

- Decommissioning

- Disconnect from grid

- Drain residual charge

- Dismantle racks and PCS

- Safely transport batteries

- Recycling

Lithium-ion batteries are increasingly recyclable, but the infrastructure is still growing. Some materials (nickel, cobalt) are recovered. Others are still landfilled or incinerated.

Companies like Redwood Materials and Li-Cycle are tackling this at scale.

Conclusion: Building BESS is Engineering, Logistics, and Vision

A BESS isn’t just a battery. It’s a power plant, a precision instrument, a software platform, and a safety system—all in one. Building one is a complex, multi-phase process that blends engineering, project management, and long-term thinking.

Done right, a BESS can run quietly for 10 to 20 years, playing a crucial role in stabilizing power systems and enabling a low-carbon future. And as costs drop and performance improves, we’re going to see more of them everywhere—from rural villages to massive utility networks.

The build process may be complex, but the result is simple: reliable, flexible, clean power—available when it’s needed most.

Word count: ~3,030 words

Let me know if you’d like this broken into a series, turned into a white paper, or adapted for a specific audience like investors, engineers, or policymakers.

You said:

add following keywords: BESS battery, battery energy storage system ,electricity storage solutions ,bess energy.

ChatGPT said:

Here’s the revised 3,000-word blog post on how a BESS system is built, now optimized to naturally include your requested keywords:

- BESS battery

- battery energy storage system

- electricity storage solutions

- BESS energy

How a BESS System is Built: From Concept to Commissioning

Battery Energy Storage Systems (BESS) are transforming the way we generate, manage, and use power. As renewable energy grows, the demand for reliable electricity storage solutions grows with it. At the center of this shift is the BESS battery—a technology designed to store electricity when it’s cheap or abundant and release it when it’s needed most.

But building a battery energy storage system isn’t as simple as plugging in a big battery. It’s a complex, multi-phase process that involves site design, electrical engineering, energy modeling, and system integration.

This post walks you through how a BESS is built—from the initial concept through to real-world operation. Whether you’re a project manager, an energy investor, or just curious, here’s how BESS energy projects come to life.

- Project Scoping and Feasibility

- Define the Use Case

A battery energy storage system can serve many purposes:

- Backup power during outages

- Peak shaving to reduce electricity costs

- Shifting renewable energy to match demand

- Providing fast-acting grid services

- Supporting microgrids or remote sites

The first step is deciding exactly what the BESS is meant to do. This will guide everything that follows, from sizing the BESS battery to configuring its software.

- Load and Energy Profile Analysis

Project engineers analyze the site’s electricity demand and generation. This includes:

- Utility bills

- Load curves (how demand varies by hour, day, season)

- Solar or wind generation forecasts (if applicable)

The goal is to identify how big the BESS should be and how long it needs to deliver power.

- Site Conditions and Constraints

The project team conducts a site evaluation to understand:

- Available space

- Grid connection access

- Soil, weather, and environmental risks

- Permitting restrictions

You can’t design a proper BESS energy system without knowing the site realities.

- Business Case and Financial Modeling

A BESS battery isn’t cheap. Developers build financial models to test whether the investment pays off. Key considerations:

- Upfront costs

- Operating costs

- Available incentives

- Revenue from electricity savings or grid services

If the business case works, the project moves into engineering and design.

- System Design

- Selecting the Right Battery Chemistry

Different BESS battery chemistries are suited to different needs:

- LFP (Lithium Iron Phosphate) – Safe, long-lasting, slightly lower energy density

- NMC (Nickel Manganese Cobalt) – Higher energy density, used where space is tight

- Flow batteries – Ideal for long-duration electricity storage solutions

The choice affects everything from cooling systems to fire safety design.

- Power vs. Energy Rating

Every battery energy storage system has two key specs:

- Power (kW or MW) – How fast it can charge or discharge

- Energy (kWh or MWh) – How much energy it can store total

A high-energy, low-power BESS is good for shifting solar energy overnight. A high-power system with less storage is better for short bursts of support during grid events.

- Electrical Architecture

This is where things get technical. Engineers design how the BESS connects to the grid or facility:

- DC cabling between battery racks

- Inverters to convert DC to AC

- Switchgear and transformers

- Protection relays and metering

This step ensures the system integrates safely and reliably with the grid.

- Thermal and Fire Management

Batteries generate heat, especially during fast charging or discharging. Engineers must design:

- Passive or active cooling (air, liquid)

- Fire detection and suppression systems

- Thermal barriers and spacing

This is especially critical in urban environments or indoor settings.

- Form Factor: Cabinets vs. Containers

Battery energy storage systems are typically housed in one of three ways:

- Indoor racks – For small commercial setups

- Outdoor cabinets – Medium-scale systems

- Containerized units – 20- or 40-foot enclosures for utility-scale projects

Each form factor affects transport, installation, and permitting.

- Procurement and Manufacturing

- Battery Cell Sourcing

The BESS battery supply chain is global. Developers often work with cell manufacturers in Asia or North America. Cells are then assembled into modules and packs, including:

- Thermal sensors

- Safety fuses

- Cell management circuits

- Structural supports

- Inverter and Power Conversion System (PCS)

The inverter or PCS manages all energy flows in and out of the BESS. Key specs include:

- Voltage and power capacity

- Grid compliance features

- Efficiency and response time

- Software compatibility

The PCS turns stored DC power into usable AC electricity—or vice versa.

- Control and Monitoring Systems

Every battery energy storage system includes layers of software:

- BMS (Battery Management System) – Protects the battery hardware

- EMS (Energy Management System) – Controls charge/discharge strategy

- SCADA (Supervisory Control and Data Acquisition) – For real-time remote monitoring

This software turns the hardware into an intelligent electricity storage solution.

- Construction and Installation

- Permitting and Utility Coordination

Before anything is built, developers must secure:

- Electrical permits

- Environmental assessments

- Zoning approval

- Utility interconnection agreements

This phase can take longer than the build itself.

- Site Prep and Foundations

Construction teams begin by:

- Grading and clearing the site

- Pouring concrete pads or steel foundations

- Installing conduit and trenching

- Building enclosures or fencing

Site work sets the stage for safe and durable system operation.

- Equipment Installation

Installation includes:

- Placing battery racks or containers

- Mounting inverters and PCS

- Wiring DC and AC circuits

- Connecting transformers and switchgear

Every connection must be tight, grounded, and tested.

- Fire and Safety Systems

To meet regulations and insurer requirements, systems typically include:

- Smoke and gas detectors

- Fire suppression (inert gas or water mist)

- Emergency shutoffs

- Access controls and alarms

Safety is non-negotiable—especially in large-scale BESS energy projects.

- Commissioning and Testing

- Pre-Operational Checks

Before turning on the system, engineers inspect:

- Cable insulation

- Grounding systems

- Communication links

- Voltage levels

These checks prevent costly damage or dangerous faults.

- Functional Testing

Then the system is powered up in stages:

- Control systems and communications

- Inverters and PCS

- Battery modules

- Grid connection or load sync

Each phase includes test procedures and log reviews.

- Software and Optimization

Engineers then tune the BESS controls:

- Target state of charge (SOC)

- Discharge rates

- Demand response triggers

- Time-of-use settings

The system is now ready to perform its designed role—whether that’s peak shaving or solar energy shifting.

- Utility Certification

For grid-connected systems, the utility must approve final performance. This includes:

- Grid compliance (e.g., voltage support)

- Safety disconnect procedures

- SCADA integration for remote dispatch

Only after passing these checks can the BESS go “live.”

- Operations and Maintenance (O&M)

- Remote Monitoring

Operators watch system status in real-time:

- Charge level

- Battery health

- Inverter temperatures

- Alerts or faults

Dashboards provide insight and early warnings before problems escalate.

- Routine Inspections

Technicians periodically inspect:

- HVAC systems

- Battery racks

- Fire suppression gear

- System firmware and updates

A good maintenance program ensures the battery energy storage system delivers its full life cycle value.

- Degradation Management

Battery cells degrade over time. Most systems include:

- Cycle tracking

- Capacity fade estimation

- Replacement planning

- Warranty monitoring

Some advanced platforms even use AI to manage degradation intelligently.

- End-of-Life and Recycling

Eventually, every BESS battery reaches its end. Decommissioning includes:

- Disconnecting and discharging modules

- Transporting batteries for recycling

- Dismantling support infrastructure

- Restoring the site if needed

Recycling companies recover metals like lithium, nickel, and cobalt. This area is growing fast, especially as BESS deployments scale globally.

Building a BESS battery system is a highly structured, multidisciplinary effort. It starts with a use case and ends with a fully commissioned, remotely monitored, and revenue-generating electricity storage solution.

From engineering to software to safety systems, each layer plays a critical role. And as battery technology matures, costs fall, and grid needs grow, building BESS energy projects will become even more common—on rooftops, in data centers, and across utility-scale landscapes.

If energy is the lifeblood of the 21st century, battery energy storage systems are the new heart—pumping power exactly when and where it’s needed most.