What Is a Containerized BESS

The Rise of Containerized Battery Energy Storage Systems

As the world shifts toward more sustainable and reliable energy solutions, Battery Energy Storage Systems (BESS) have become essential in supporting the grid and enabling renewable integration. Among the most practical and scalable forms is the containerized BESS—a modular, pre-assembled battery solution housed in a shipping container.

Designed for quick deployment and high flexibility, containerized BESS units are gaining momentum in utility-scale energy storage, commercial installations, microgrids, and renewable energy projects. But what exactly are they, and why are they becoming so popular?

In this guide, we’ll break down the components, benefits, use cases, and key qualities of containerized BESS solutions.

“Everything You Need to Know“

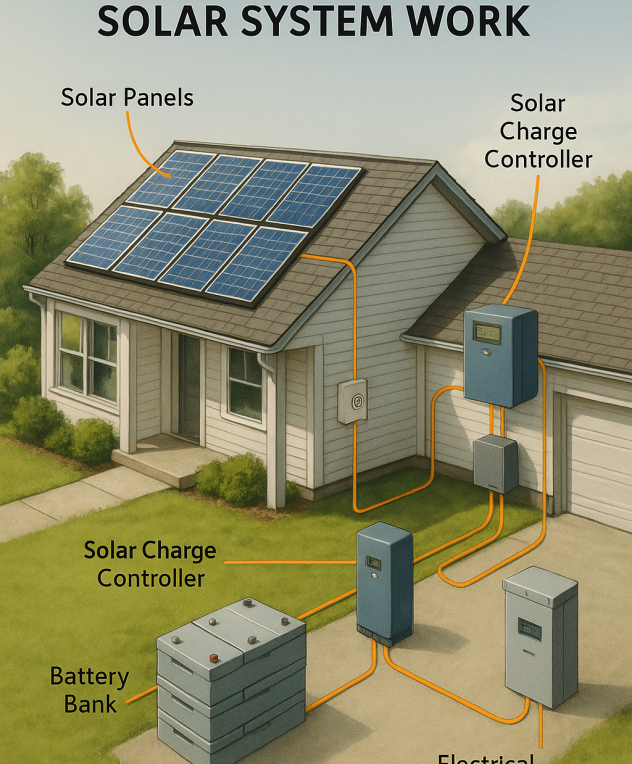

A containerized Battery Energy Storage System (BESS) is a fully integrated energy storage unit enclosed within a standard shipping container (typically 10-ft, 20-ft, or 40-ft sizes). These mobile units are designed for fast transport, plug-and-play operation, and easy integration into existing power infrastructure.

Each unit typically includes:

- Lithium ion battery modules (such as LiFePO4 or NMC chemistry)

- A Battery Management System (BMS)

- Power Conversion System (PCS)

- Fire suppression and HVAC for thermal control

- Monitoring and communication systems

Containerized BESS units are pre-engineered and pre-tested before delivery, which reduces on-site construction, speeds up commissioning, and ensures standardized performance.

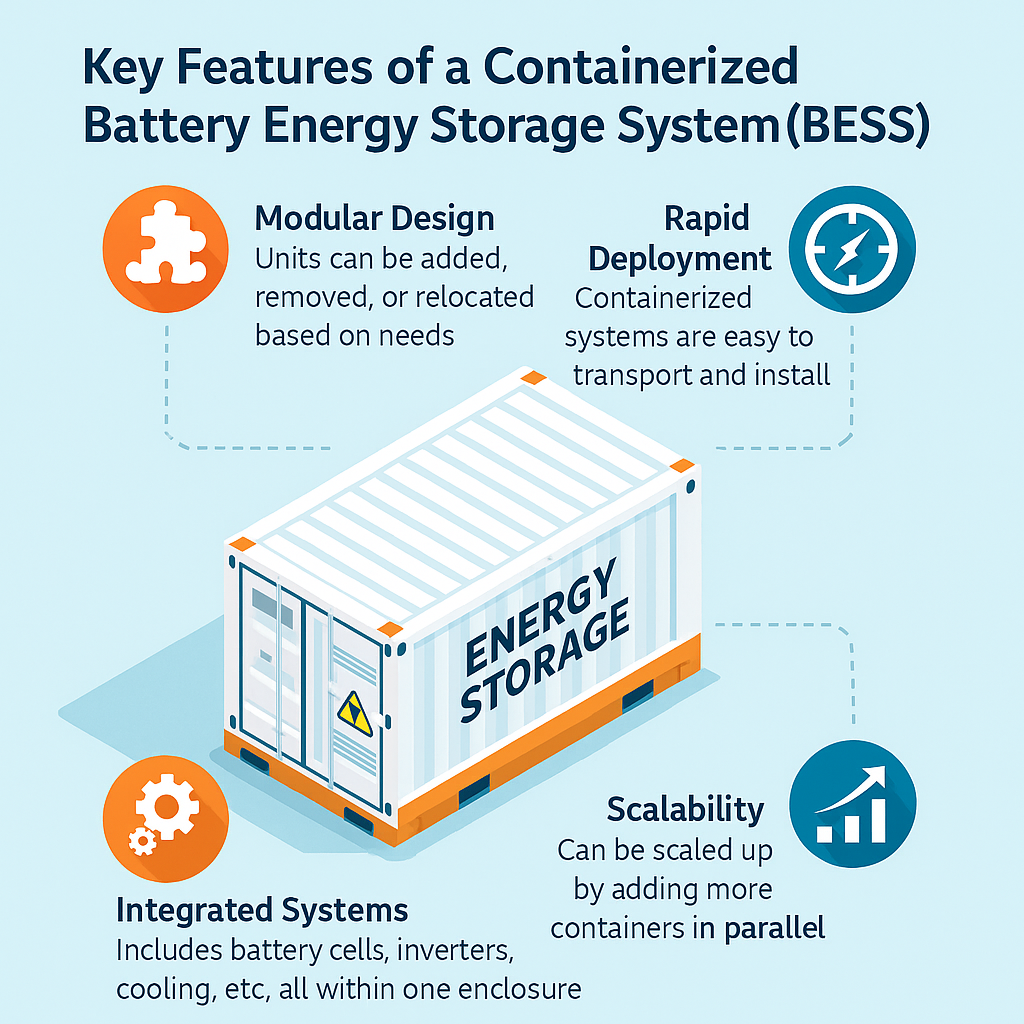

Key Features of Containerized Battery Storage Systems

- Modularity

Containerized BESS solutions are built to scale. Whether a project starts with a single unit or several, capacity can be increased by adding more containers. This modularity makes it easier to plan phased rollouts and adjust system size based on demand over time.

- Mobility

With their standardized form factor, containerized BESS units are easy to ship globally and transport via truck, train, or ship. This mobility supports temporary deployments, such as events, military bases, or construction sites, and simplifies redeployment to new locations.

- Plug-and-Play Setup

These systems are delivered fully integrated with batteries, inverters, thermal management, and controls. Once on site, setup involves minimal work—typically just electrical connection and commissioning. This significantly reduces labor and project timelines compared to traditional builds.

- Environmental Protection

Built to withstand outdoor conditions, containers are sealed and ruggedized. They are often IP-rated against dust and water ingress and include HVAC systems to manage internal temperatures. This ensures reliable performance in deserts, coastal regions, or cold climates.

- Safety and Compliance

Advanced BESS units incorporate multi-layered safety systems including fire suppression, gas detection, thermal sensors, and emergency shutdown. These features comply with industry standards such as UL 9540A, NFPA 855, and IEC certifications, ensuring both operational safety and regulatory approval.

Use Cases for Containerized Battery Energy Storage Systems

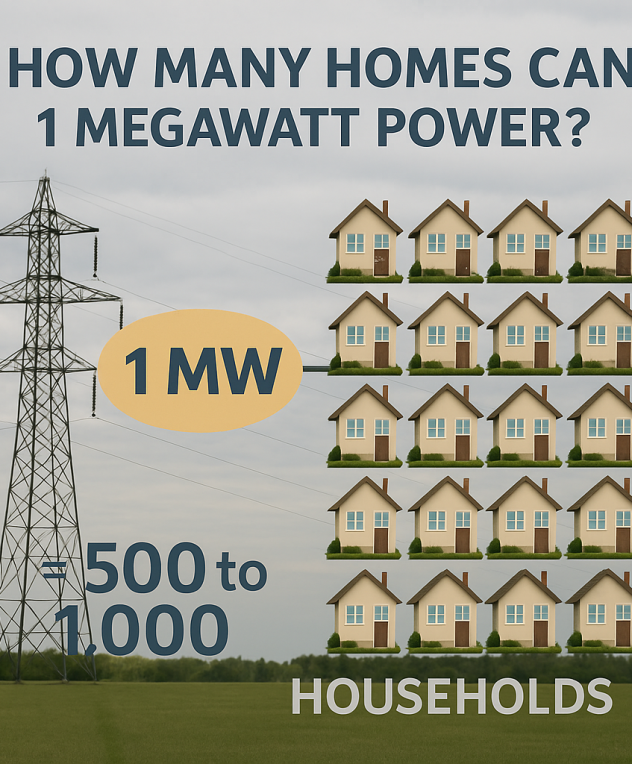

Modular Utility Scale Energy Storage

Containerized BESS units are designed for easy scaling in utility applications. Multiple units can be deployed in parallel to provide grid-scale storage that supports renewable integration, peak load reduction, and capacity firming. Their modular nature enables phased expansion and integration with existing grid infrastructure.

Battery Energy Storage Container

These all-in-one containers simplify deployment by combining high-capacity batteries with power electronics and climate control in a single enclosure. This reduces project complexity and ensures quick on-site installation and testing, making them ideal for both permanent and mobile storage applications.

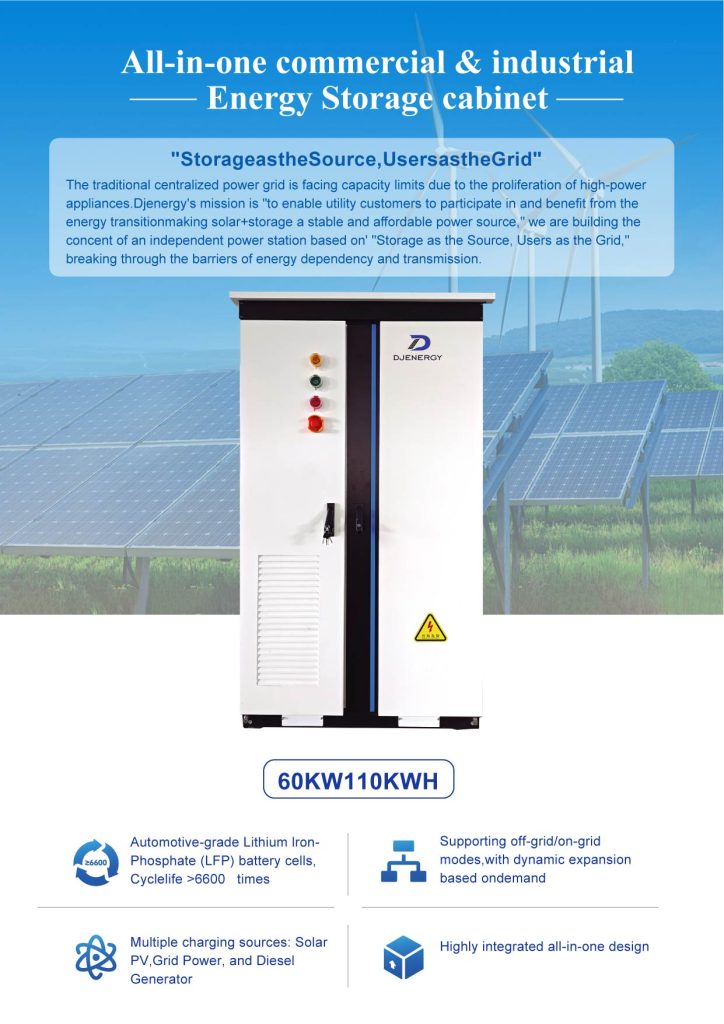

Solar Battery Container

Pairing solar PV arrays with containerized battery systems allows for seamless energy capture and dispatch. These systems store excess solar production during the day and discharge it during peak hours or at night, helping maximize solar investment and achieve energy independence.

Container Battery System

Container battery systems offer rugged, weather-resistant energy solutions suitable for remote or temporary sites. Their transportability makes them useful for grid-tied and off-grid setups, including field operations, mobile EV charging, or temporary energy storage hubs.

Lithium Ion Battery Storage

Most containerized BESS deployments today use lithium ion batteries due to their high energy density, long cycle life, and fast charging capabilities. They support frequent cycling and maintain high efficiency across varied applications, from commercial microgrids to utility scale services.

Microgrid Battery System

Containerized BESS are ideal for hybrid and renewable-powered microgrids, enabling energy balancing, backup power, and load optimization. Used in both islanded and grid-connected modes, they enhance resilience and reduce diesel dependence in off-grid communities and industrial campuses.

Common Applications of Containerized BESS

- Utility-Scale Energy Storage

Containerized BESS units support grid stability by absorbing excess energy during periods of low demand and discharging it during peak hours. This not only helps utilities meet demand but also enhances grid reliability and defers infrastructure upgrades.

- Renewable Energy Projects

Wind and solar power are intermittent by nature. Containerized BESS stores surplus energy generated during sunny or windy periods and delivers it during cloudy or calm weather. This improves renewable penetration and reduces reliance on fossil backup.

- Commercial and Industrial Facilities

For large energy consumers like factories, data centers, and office campuses, containerized battery storage reduces peak demand charges, provides critical backup during outages, and supports participation in demand response programs.

- Microgrids and Remote Areas

Off-grid villages, island communities, and remote installations can rely on containerized BESS to reduce diesel generator use, lower emissions, and provide consistent power. These systems enable solar-powered microgrids with minimal maintenance and scalable capacity.

- Emergency and Disaster Relief

In crisis scenarios such as hurricanes, wildfires, or earthquakes, containerized BESS can be rapidly deployed to power shelters, mobile hospitals, and command centers. Their mobility and fast setup are critical for disaster resilience and humanitarian aid.

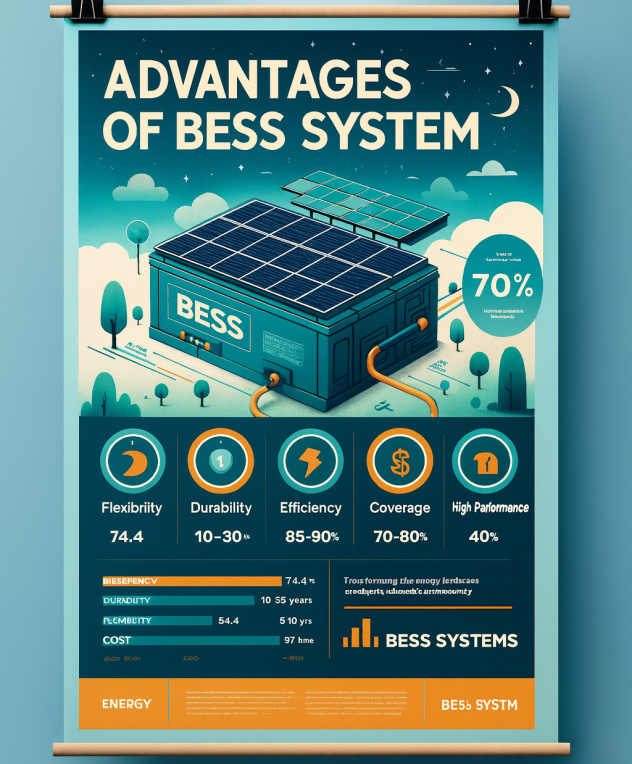

Benefits of Containerized BESS

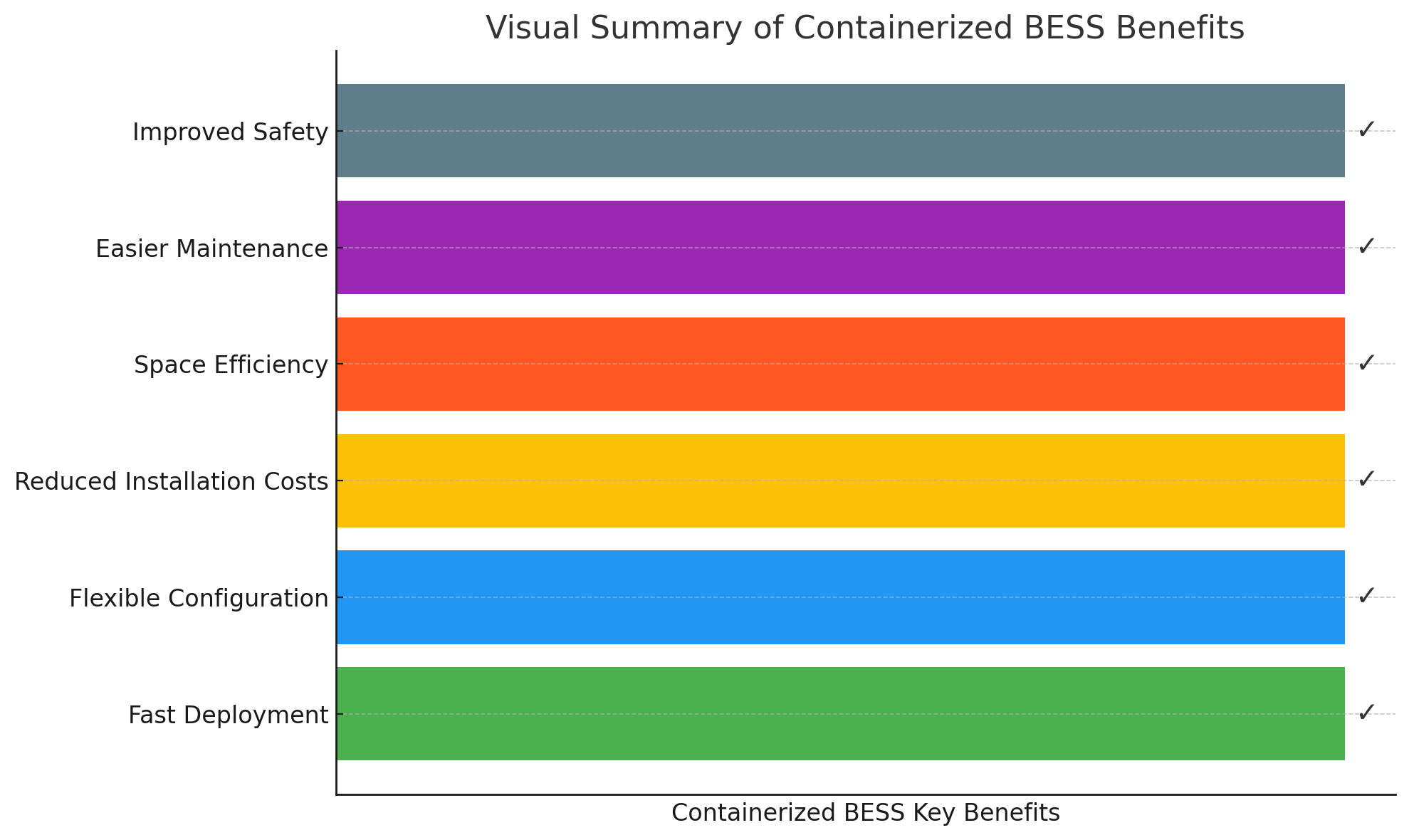

Fast Deployment

Containerized BESS solutions arrive pre-assembled and pre-tested, significantly reducing the time from delivery to operation. They can be installed and commissioned within days, making them ideal for urgent grid stabilization or emergency backup needs.

Flexible Configuration

These systems can be configured for a variety of grid services such as peak shaving, frequency regulation, demand response, energy arbitrage, or backup power. Operators can customize control strategies depending on their operational goals.

Reduced Installation Costs

The all-in-one container format eliminates the need for expensive civil works, dedicated battery rooms, or complex integration on site. Minimal construction and wiring result in significant cost savings and streamlined permitting.

Space Efficiency

Designed to hold high-capacity battery arrays in a condensed footprint, containerized BESS is suitable for urban installations, commercial lots, and remote outposts where space is limited. Containers can even be stacked or placed side by side to maximize use of available land.

Easier Maintenance

Standardized layout, central control access, and replaceable components make maintenance more predictable and manageable. Many systems include remote monitoring features for proactive diagnostics and maintenance scheduling.

Improved Safety and Regulation Compliance

Integrated fire suppression, battery management systems, and environmental controls enhance safety. Compliance with certifications like UL 9540A and NFPA 855 ensures the system is suitable for deployment in commercial, industrial, and public spaces.

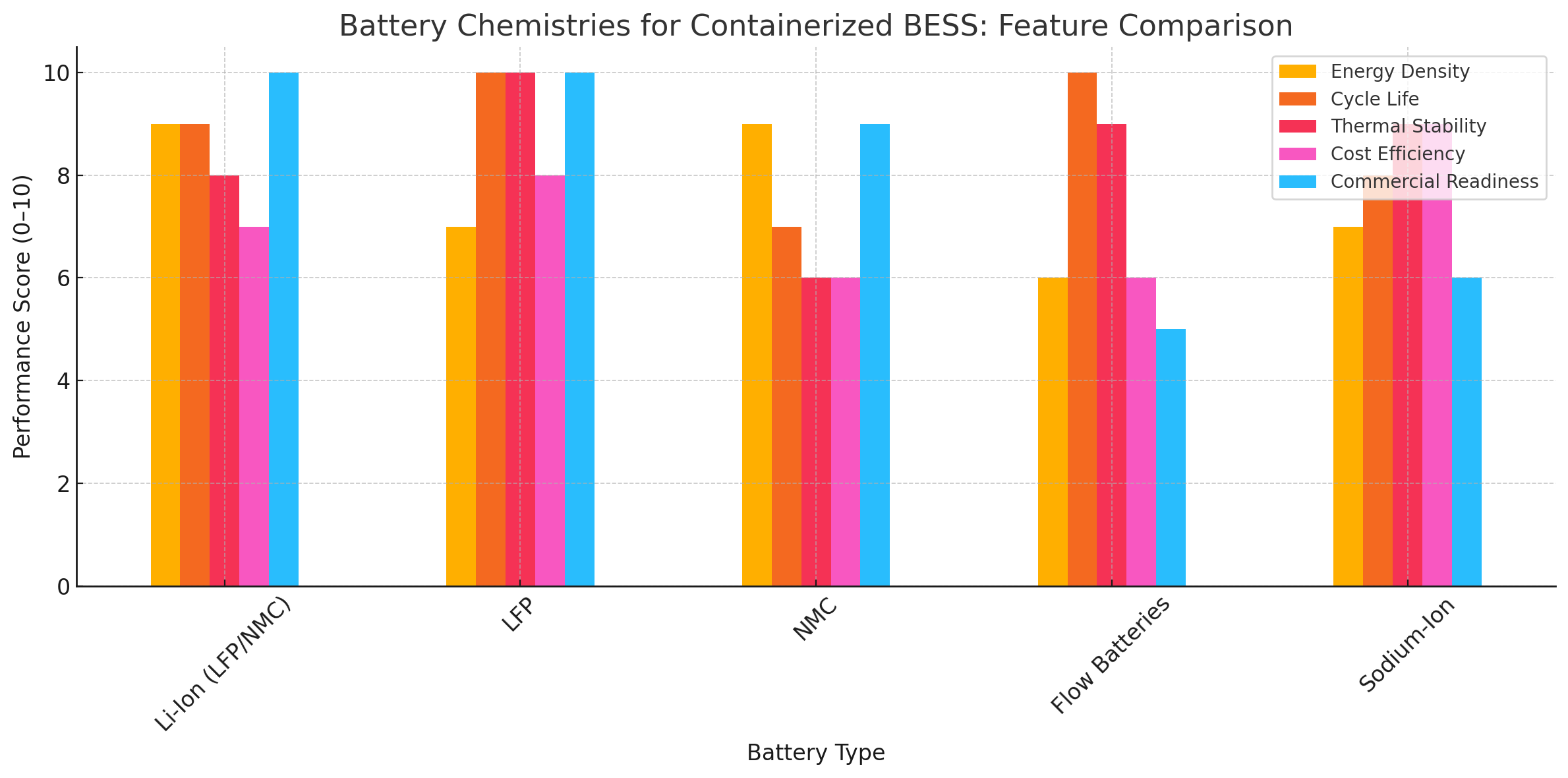

Battery Chemistry Used in Containerized BESS

The choice of battery chemistry significantly influences the performance, cost, and safety of containerized BESS. Below are the most commonly used types:

- Lithium Ion (LiFePO4 or NMC): The industry standard for containerized energy storage. Lithium ion chemistries offer high energy density, compact design, and excellent cycle life. They’re suited for both short-duration and long-duration storage and feature advanced thermal and safety control systems.

- LFP (Lithium Iron Phosphate): A subtype of lithium ion, LFP is known for its exceptional thermal stability, longer lifespan, and safer operation under high-stress conditions. LFP is favored in hot climates and applications requiring deep cycling.

- NMC (Nickel Manganese Cobalt): Offers higher energy density than LFP, making it a good fit for space-limited environments. However, it typically has a shorter lifespan and is more sensitive to overheating, requiring robust thermal management.

- Flow Batteries: Though less common in containerized formats, flow batteries store energy in liquid electrolytes separated by membranes. They’re ideal for long-duration applications (e.g., 4–12+ hour discharge), with minimal degradation over thousands of cycles.

- Sodium-Ion and Emerging Chemistries: New entrants like sodium-ion and zinc-air are being evaluated for containerized formats due to their low-cost, non-toxic materials, and growing commercial interest for long-duration and low-temperature applications.

Is a Containerized BESS Right for You?

If you’re looking for scalable, fast-to-deploy energy storage, a containerized BESS offers an all-in-one solution. With plug-and-play setup, rugged build quality, and support for high-performance lithium battery chemistries, these systems are revolutionizing how we deliver and store energy across commercial, utility, and remote applications.

As renewable energy becomes the backbone of global electricity, containerized battery storage ensures that power is always available—anywhere it’s needed.

How to Choose a Containerized BESS

Choosing the right containerized BESS involves evaluating key operational, technical, and site-specific requirements to ensure optimal energy storage performance and scalability

Step 1: Define Your Use Case

Begin by clearly identifying your energy storage objectives. Are you managing peak loads, supporting a renewable energy system, providing emergency backup, or stabilizing the grid? The use case dictates the necessary discharge time, power capacity, and control system complexity.

Step 2: Estimate Required Capacity and Power

Determine the daily and hourly energy demands of your site. Consider not just the average but also peak usage. This helps you size the system in kilowatt-hours (kWh) and identify whether you need high power (kW) output for short bursts or lower power over extended periods.

Step 3: Evaluate Battery Chemistry and Lifespan

Select a battery chemistry based on environmental conditions, lifespan expectations, budget, and safety needs. Lithium ion (especially LFP) is ideal for high-cycle, high-performance applications. For cost-sensitive, longer-duration projects, emerging chemistries like sodium-ion may be considered.

Step 4: Check Environmental Ratings

Ensure the container is suitable for your climate. Look for weatherproof designs, built-in HVAC systems, and certifications like IP65, which confirm protection against dust and water ingress. Climate-specific features improve lifespan and performance stability.

Step 5: Consider Monitoring and Safety Features

Advanced containerized BESS come equipped with real-time monitoring systems, thermal controls, and fire suppression technologies. Choose a system that integrates with SCADA, EMS, or cloud dashboards for analytics, alerts, and remote diagnostics.

Step 6: Assess Scalability and Maintenance Support

Opt for modular systems that allow capacity expansion as your energy needs grow. Verify that technical support, spare parts, and service agreements are available for long-term operations, especially in remote or high-demand environments.